CPS testing laboratories are equipped with advanced equipment and are part of our comprehensive quality control program. These laboratories allow us to accurately test battery in order to obtain the maximum efficiency according to customer specifications for the batteries.

Every battery from us goes through at least 4 QC checkpoints before meeting the customers. So far the overall defect rate of our batteries is ≤0.3% reported by customers.

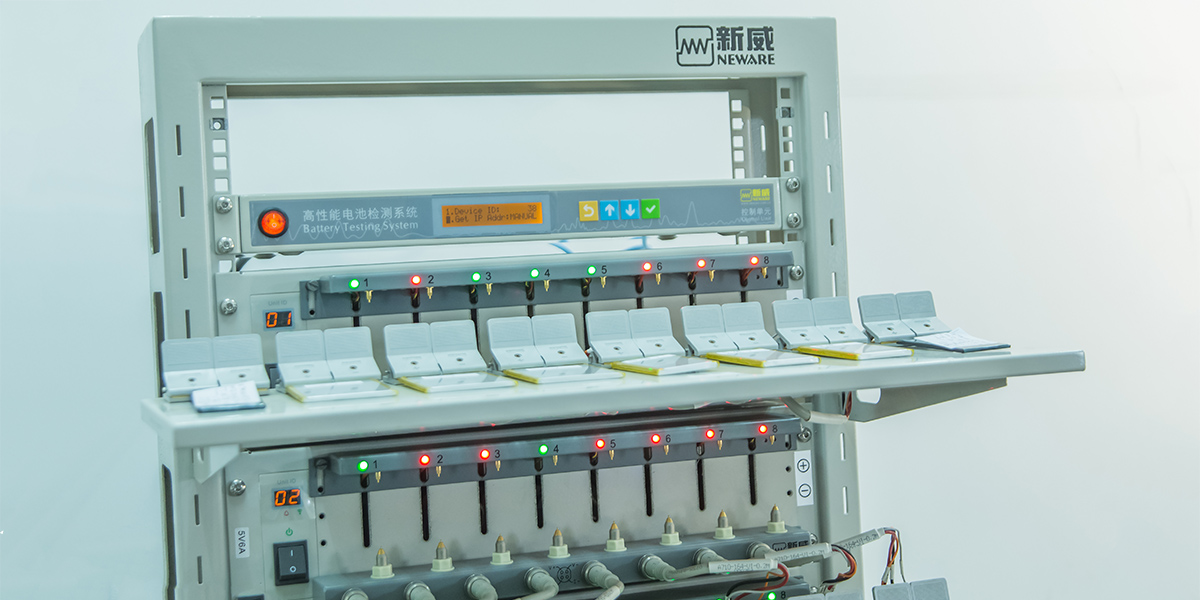

1.Screening of Battery Cell- capacity

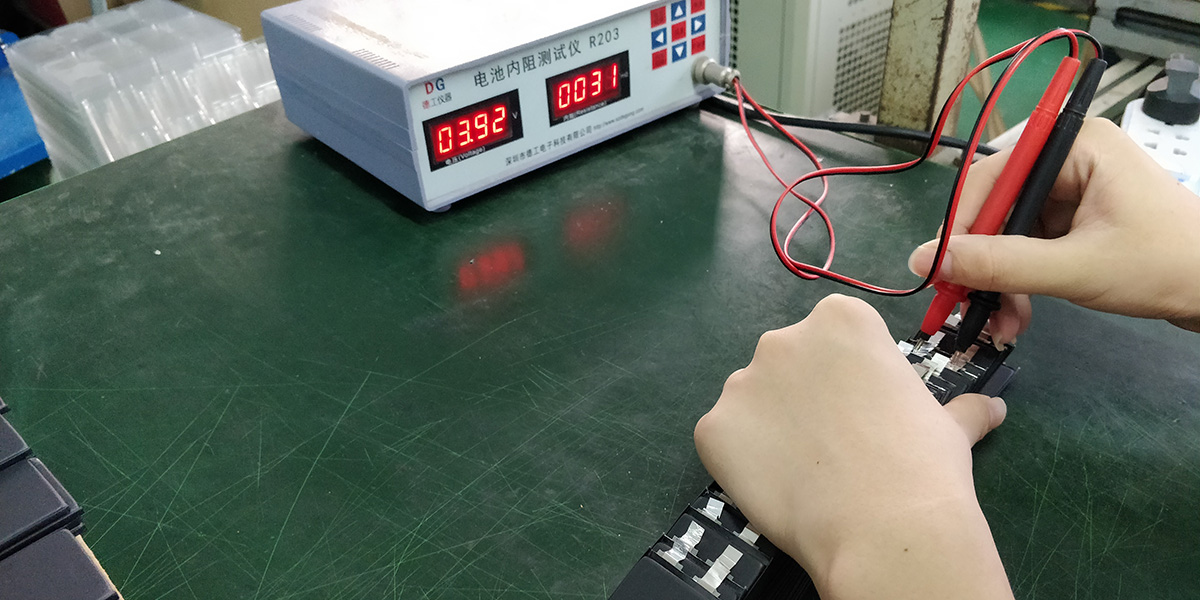

2.Battery Cell Testing- voltage, resistance

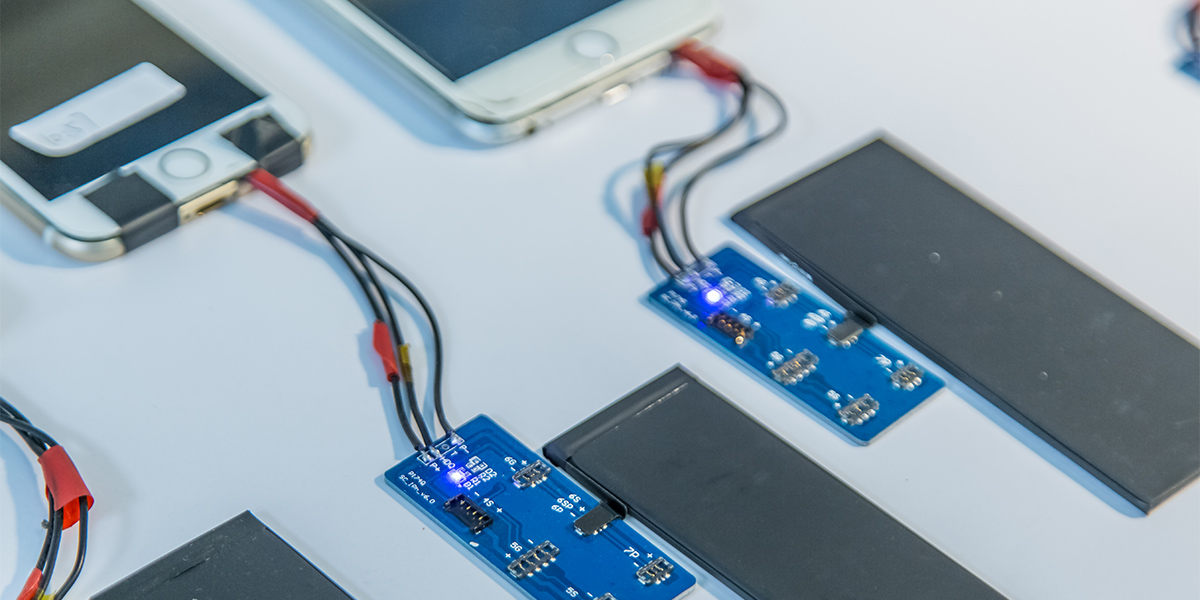

3.Protection Board Testing

4.Semi-finished Battery Testing

5.Finished Battery Testing

6.Sampling Test- 500 cyles -force charge & discharge

7.Sampling Test with iPhone

8.High & low-temperature test

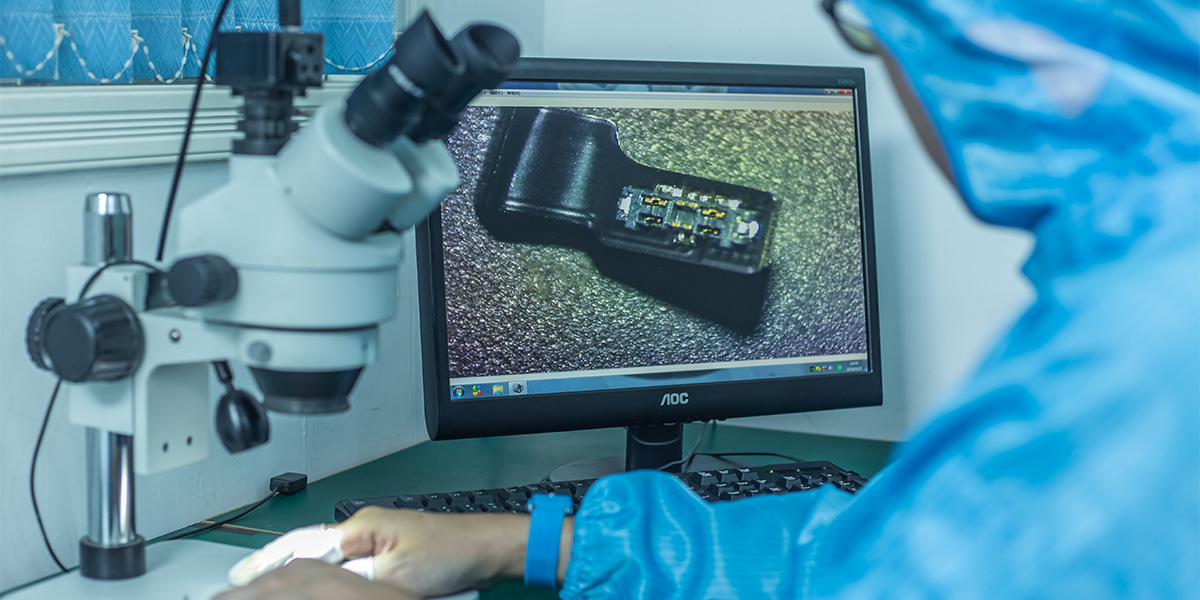

9.Connector inspection

Crush Test

Battery Condition :Fresh, fully-charged

Test Method :Crush between two flat plates. The applied force is about 13.0kN±0.78kN (1.72Mpa) for 30min

Requirements:No explosion, no fire

Short Circuit Test (Normal Temperature)

Battery Condition :Fresh, fully-charged

Test Method:The cell is to be short-circuited by connecting the positive and negative terminals of the cell directly with copper wire with a resistance of less than 80mΩ±20mΩ. Tests are to be conducted at room temperature (20±2℃)

Requirements:No explosion, no fire

Impact Test

Battery Condition :Fresh, fully-charged

Test Method :A test sample battery is to be placed on a flat surface. A 5/8-inch (15.8mm) diameter bar is to be placed across the center of the sample. A 20-pound (9.1kg) weight is to be dropped from a height of 24 ±1 inch (610±25mm) onto the sample

Requirements:No explosion, no fire

Thermal Shock Test

Battery Condition:Fresh, fully-charged

Test Method :After standard charging, heat the cell to 130±2 ℃ at a rate of 5±2℃ /min and keep the cell at this temperature for 30 minutes

Requirements:No explosion, no fire

Overcharge Test

Battery Condition: Fresh, fully-charged

Test Method: Charge at 3ItA till 4.6V for 7 hours

Requirements: No explosion, no fire

Shock Test

Battery Condition: Fresh, fully-charged

Test Method: 6 times spontaneous dropping from 0.45m to a surface of hardwood (thickness: over 10mm)

Requirements: No explosion, no fire, the cell shall be normality in appearance, no less than 90% in terminal voltage